Introduction

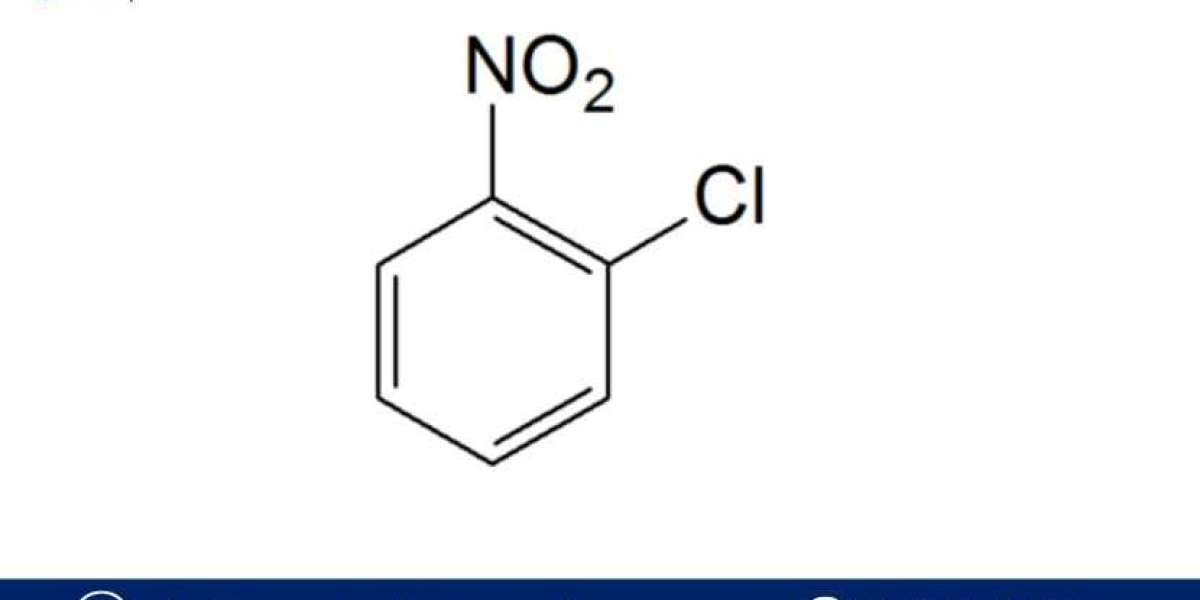

Ortho Nitro Chloro Benzene (ONCB) is an important industrial chemical used as an intermediate in the production of a variety of chemicals. It is primarily used in the manufacture of agrochemicals, dyes, and pharmaceuticals, making it a key compound in several industries. The demand for ONCB is driven by its widespread applications in the production of herbicides, pesticides, and other essential chemical formulations. The growing global chemical industry, especially in developing countries, presents a significant opportunity for establishing a manufacturing plant dedicated to the production of Ortho Nitro Chloro Benzene. An Ortho Nitro Chloro Benzene Manufacturing Plant focuses on the large-scale production of this key chemical by utilizing raw materials like nitrobenzene and chlorine. The process involves a highly controlled chemical reaction under precise conditions to produce ONCB in a pure form. The plant must adhere to strict safety, environmental, and quality standards during production. This Ortho Nitro Chloro Benzene Manufacturing Plant Project Report outlines the steps involved in setting up an ONCB manufacturing plant, covering everything from market dynamics and production processes to raw materials, operational costs, and revenue potential.

Market Overview

Demand for Ortho Nitro Chloro Benzene

Ortho Nitro Chloro Benzene is an essential intermediate chemical in various industries. The demand for ONCB is primarily driven by its applications in several sectors:

Agriculture: ONCB is a key precursor in the manufacture of herbicides, fungicides, and pesticides. The growing demand for effective and environmentally safe agrochemicals to meet the challenges of modern agriculture continues to drive the need for ONCB.

Pharmaceuticals: ONCB is used in the synthesis of various pharmaceutical intermediates, especially those involved in the production of analgesics, antibiotics, and other essential medicines.

Dyes and Pigments: The chemical is used in the manufacturing of dyes, particularly azo dyes, which are widely used in textiles, food coloring, and cosmetics.

Specialty Chemicals: As an intermediate in various chemical reactions, ONCB plays a crucial role in the synthesis of other specialty chemicals used in various industries, including plastics, resins, and other fine chemicals.

Get a Free Sample Report with Table of Contents@

Growth of the Chemical Industry

The global chemical industry has witnessed significant growth over the past few decades, with Asia-Pacific being a major contributor to the increase in chemical production. In countries like China and India, the chemical industry has seen rapid expansion, driven by industrialization, urbanization, and the demand for consumer products. This growth has created an expanding market for chemicals like Ortho Nitro Chloro Benzene.

Additionally, increasing investments in agriculture and the rise of the pharmaceutical and textile industries in emerging markets further contribute to the demand for ONCB. The growing regulatory focus on environmental and safety standards has also spurred innovation in the agrochemical and pharmaceutical sectors, with ONCB being a critical component in the development of new, safe chemical products.

Key Markets and Regions

Asia-Pacific: Countries in Asia, such as China and India, represent the largest and fastest-growing markets for ONCB. The region's booming agriculture and textile industries have led to higher demand for ONCB in the production of agrochemicals and dyes.

North America: The demand for ONCB in North America is driven by its application in specialty chemicals and pharmaceuticals. While the region is home to established manufacturing plants, the ongoing demand for high-quality agrochemicals and pharmaceutical intermediates contributes to market growth.

Europe: In Europe, ONCB is used mainly in the production of pharmaceutical products and agrochemicals. The demand for environmentally friendly and innovative chemical solutions is high in this region, leading to a stable market for ONCB.

Regulatory Landscape

The production and use of Ortho Nitro Chloro Benzene are regulated by environmental and safety standards to minimize risks associated with its toxicity and chemical properties. The manufacturing plant must adhere to local, national, and international safety guidelines regarding chemical handling, storage, and disposal to ensure a safe working environment and compliance with regulations.

Production Process

The production of Ortho Nitro Chloro Benzene involves the chlorination of nitrobenzene under controlled conditions. The key steps in the manufacturing process include:

1. Raw Materials and Chemical Reactions

The two primary raw materials used in the production of ONCB are nitrobenzene and chlorine. The production process typically involves the following reactions:

Chlorination of Nitrobenzene: In the presence of a catalyst, nitrobenzene undergoes chlorination using chlorine gas, which results in the formation of Ortho Nitro Chloro Benzene. The reaction is carefully monitored to control the temperature, pressure, and reaction time to achieve high yields and minimize by-products.

Purification: The crude product is then purified to remove any residual impurities or unreacted materials. This may involve processes like filtration, distillation, and recrystallization.

2. Reactor Setup

A well-designed reactor system is essential to ensure a controlled and efficient chlorination reaction. The reactor must be capable of maintaining the necessary temperature and pressure conditions to promote the reaction while ensuring safety. The reactor may also be equipped with mixing and cooling systems to regulate the reaction environment.

3. Post-Reaction Treatment

After the chlorination process, the product is treated to remove any remaining unreacted chlorine or other impurities. This may involve washing with solvents or neutralization with alkaline solutions. The purified Ortho Nitro Chloro Benzene is then dried and processed for packaging.

4. Quality Control

Throughout the production process, strict quality control measures are implemented to ensure that the final product meets the required specifications. Laboratory tests and sampling are conducted at various stages to monitor parameters such as purity, color, and chemical composition.

5. Packaging

Once the ONCB has been produced and tested, it is packaged into appropriate containers for storage and distribution. Packaging materials must be chosen to protect the product from contamination and degradation during storage and transport.

Raw Materials

The major raw materials required for the production of Ortho Nitro Chloro Benzene are:

- Nitrobenzene: Nitrobenzene is the primary starting material and is readily available from chemical suppliers.

- Chlorine: Chlorine is used in the chlorination process to form ONCB. It is typically sourced from chlorine gas suppliers.

- Catalysts and Solvents: Depending on the specific manufacturing process, catalysts and solvents may be required to facilitate the reaction and improve product yields.

Other auxiliary materials may include various chemicals for purification and neutralization, along with packaging materials such as drums or bottles.

Plant Setup and Infrastructure

Setting up a manufacturing plant for Ortho Nitro Chloro Benzene involves several key considerations:

1. Location and Facilities

The plant should be located in an industrial zone with good access to raw materials, transportation routes, and utilities. The facility must include the following:

- Production Area: The main area where the chemical reactions, purification, and packaging will take place.

- Storage and Warehousing: Space for storing raw materials and finished products.

- Quality Control Laboratory: An area dedicated to testing raw materials, intermediates, and finished products.

- Utilities: Systems for water, electricity, and waste management, ensuring smooth operations.

2. Safety and Environmental Compliance

Given the hazardous nature of chemicals involved in the production of ONCB, the plant must implement stringent safety protocols, including proper ventilation, fire prevention measures, and emergency response systems. It must also comply with environmental regulations to manage waste disposal and emissions effectively.

3. Machinery and Equipment

The plant will require specialized equipment for the chlorination process, including reactors, filtration units, distillation columns, and drying equipment. Automated packaging lines will also be necessary to handle the finished product efficiently.

4. Labor Force

The plant will require skilled personnel to manage the production process, including operators, chemical engineers, quality control analysts, and safety officers. Adequate training programs must be provided to ensure safety and efficiency in operations.

Operational Costs

The operational costs for an Ortho Nitro Chloro Benzene manufacturing plant include:

- Raw Materials: The cost of nitrobenzene, chlorine, catalysts, solvents, and packaging materials.

- Labor Costs: Wages for plant workers, engineers, and administrative staff.

- Energy: Electricity and water for the production process, heating, cooling, and other operations.

- Maintenance and Repairs: Regular maintenance of reactors, purification systems, and packaging equipment.

- Regulatory Compliance: Costs related to safety, environmental management, and certifications.

Revenue Potential

The revenue generated by an Ortho Nitro Chloro Benzene manufacturing plant is largely dependent on the demand for ONCB in various industries, including agrochemicals, pharmaceuticals, and dyes. The plant can achieve steady revenue by supplying ONCB to industrial customers, which include manufacturers of pesticides, herbicides, pharmaceuticals, and specialty chemicals.

Pricing Strategy

The pricing of ONCB is determined by factors such as raw material costs, production efficiency, market demand, and competition. Pricing strategies must be designed to ensure competitiveness in the market while covering operational costs and generating profits.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au