Heat pipes are essential components in thermal management, offering highly efficient heat transfer solutions for a wide range of industries, from electronics and telecommunications to aerospace and automotive. Choosing the right heat pipe manufacturer is key to ensuring that your project benefits from quality products and reliable performance. Here are the critical factors to consider when selecting a heat pipe manufacturer.

Manufacturing Expertise and Experience

The first factor to consider when choosing a heat pipe manufacturer is their level of expertise and experience in the industry. A reputable manufacturer should have a proven track record in designing and producing high-performance heat pipes for various applications. Manufacturers with deep technical knowledge can provide solutions tailored to your specific thermal management needs. They should be well-versed in working with different materials, wick structures, and pipe configurations to create heat pipes that meet the unique demands of your project.

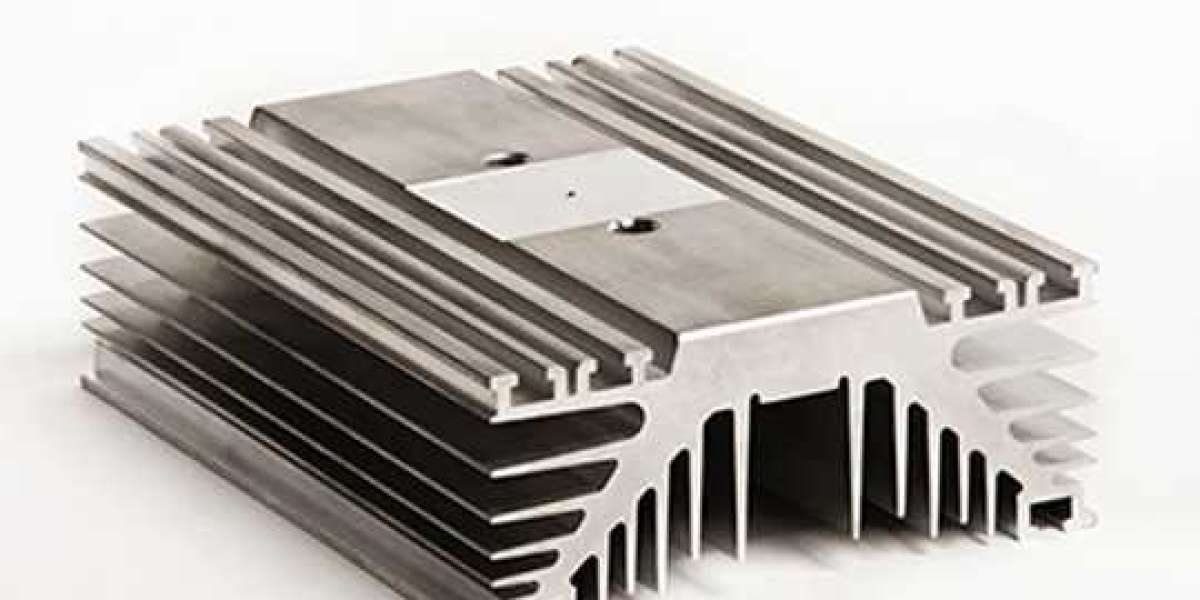

Experienced manufacturers will also be familiar with various heat pipe technologies, including copper heat pipes, aluminum heat pipes, and advanced heat pipe systems like vapor chambers and loop heat pipes. Partnering with a manufacturer that has extensive experience across multiple industries ensures they have the know-how to address complex thermal challenges.

Customization and Design Flexibility

Not all heat pipes are created equal, and many projects require customized solutions. A reliable heat pipe manufacturer should offer design flexibility, allowing for custom heat pipes that meet the precise specifications of your application. This includes the ability to customize pipe dimensions, shapes, wick structures, and working fluids to optimize heat transfer.

Manufacturers that provide custom heat pipe solutions are often better equipped to address thermal management challenges in specific industries, such as high-performance computing, aerospace, and medical devices. Their ability to deliver tailored solutions ensures the highest level of thermal efficiency, especially for non-standard or high-performance applications.

Quality Assurance and Industry Certifications

The quality of the heat pipes produced is crucial to ensuring their long-term performance. A trusted heat pipe manufacturer will adhere to strict quality control processes and industry standards to deliver consistent, high-quality products. Look for manufacturers that are certified under ISO 9001 or other relevant industry certifications, as these credentials demonstrate a commitment to maintaining high standards throughout the manufacturing process.

Additionally, manufacturers should perform rigorous testing of their heat pipes to ensure reliability, durability, and performance under various conditions. Quality assurance processes, including thermal testing, pressure testing, and material verification, ensure that the heat pipes will function as expected in demanding environments.

Advanced Manufacturing Capabilities

The right heat pipe manufacturer should have state-of-the-art production facilities with advanced manufacturing capabilities. This includes the ability to produce both standard and custom heat pipes in large quantities without sacrificing quality. Manufacturers with modern machinery and efficient production lines can handle high-volume orders while maintaining precision and consistency.

It's also important to assess whether the manufacturer uses the latest technologies, such as automated extrusion and CNC machining, to create high-quality heat pipes. These technologies can help achieve tighter tolerances and better surface finishes, which are essential for maximizing the heat transfer capabilities of the pipes.

Lead Times and Scalability

For time-sensitive projects, fast turnaround times and the ability to scale production are critical. When selecting a heat pipe manufacturer, inquire about their lead times and production capacity. A reliable manufacturer should be able to meet your project’s deadlines and scale production based on your needs. Whether you require a small batch for prototyping or a large-scale production run, the manufacturer should have the resources and capacity to accommodate your project without compromising quality or delivery timelines.

Technical Support and After-Sales Service

Working with a heat pipe manufacturer that provides strong technical support is essential for ensuring a smooth production process. Look for manufacturers that offer design consultation, thermal analysis, and prototyping services. They should be able to work with your engineering team to optimize the heat pipe design for maximum performance.

Furthermore, after-sales service is an important consideration. Choose a manufacturer that offers ongoing support, including troubleshooting, maintenance advice, and replacement parts. This ensures that any issues that arise post-installation are quickly addressed, maintaining the performance and reliability of the heat pipes in your system.

Competitive Pricing and Value

While price is always a factor in selecting a manufacturer, it’s important to balance cost with value. The cheapest option may not always provide the best long-term solution. Look for manufacturers that offer competitive pricing without compromising on quality. A reliable heat pipe manufacturer should provide detailed cost estimates and work with you to find a solution that meets your budget while delivering the required performance and durability.

In conclusion, choosing the right heat pipe manufacturer involves a careful evaluation of their experience, manufacturing capabilities, customization options, quality control processes, lead times, and technical support. By selecting a manufacturer with proven expertise and a strong commitment to quality, you can ensure that your project benefits from efficient and reliable heat pipes, contributing to the overall success of your thermal management system.